When it comes to ensuring a perfect seal, choosing the right O-ring size is crucial. O-rings are versatile components used in a variety of industries, from automotive to aerospace, and their correct sizing is essential for optimal performance. This guide will help you understand the different sizing standards and how to select the perfect O-ring for your needs.

Choosing the right O-ring involves understanding the application’s specific requirements, including temperature, pressure, chemical compatibility, material selection, and mechanical stresses. Refer to the sizing chart later in this page to find the appropriate O-ring size based on the standard you follow. If your application requires unique specifications, consider opting for custom O-rings by contacting us at Request-for-Quote to ensure a perfect fit.

How O ring Sizes are Measured?

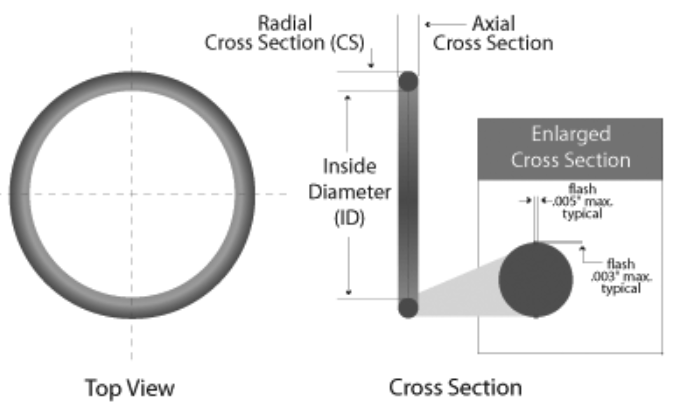

O-rings are measured using three main dimensions: the inside diameter (ID), the outside diameter (OD), and the cross-sectional diameter (CSD). Understanding these measurements is crucial for selecting the right O-ring for your application. Here’s a detailed explanation of how each dimension is measured:

The outside diameter is the distance across the outer edges of the O-ring. It is measured from one outer edge directly across to the opposite outer edge. The OD is important for ensuring the O-ring fits within the housing or cavity it is designed to seal.

The cross-sectional diameter, also known as the thickness or width, is the distance across the circular cross-section of the O-ring. It is measured by slicing the O-ring in half and measuring the distance from one side of the cross-section to the other. The CSD is vital for determining the compression and sealing capability of the O-ring.

O-Ring Sizing Chart

| AS568A-Dash # | Actual I.D. Inches | Actual C.S. Inches | Actual I.D. Millimeters | Actual C.S. Millimeters | Nominal Reference I.D. | Nominal Reference C.S. | Nominal Reference O.D. |

|---|---|---|---|---|---|---|---|

| -1 | .029±.004 | .040±.003 | 0.74±0.10 | 1.02±0.08 | 1/32 | 1/32 | 3/32 |

| -2 | .042±.004 | .050±.003 | 1.07±0.10 | 1.27±0.08 | 3/64 | 3/64 | 9/64 |

| -3 | .056±.004 | .060±.003 | 1.42±0.10 | 1.52±0.08 | 1/16 | 1/16 | 3/16 |

| -4 | .070±.005 | .070±.003 | 1.78±0.13 | 1.78±0.08 | 5/64 | 1/16 | 13/64 |

| -5 | .101±.005 | .070±.003 | 2.57±0.13 | 1.78±0.08 | 3/32 | 1/16 | 7/32 |

| -6 | .114±.005 | .070±.003 | 2.90±0.13 | 1.78±0.08 | 1/8 | 1/16 | 1/4 |

| -7 | .145±.005 | .070±.003 | 3.68±0.13 | 1.78±0.08 | 5/32 | 1/16 | 9/32 |

| -8 | .176±.005 | .070±.003 | 4.47±0.13 | 1.78±0.08 | 3/16 | 1/16 | 5/16 |

| -9 | .208±.005 | .070±.003 | 5.28±0.13 | 1.78±0.08 | 7/32 | 1/16 | 11/32 |

| -10 | .239±.005 | .070±.003 | 6.07±0.13 | 1.78±0.08 | 1/4 | 1/16 | 3/8 |

| -11 | .301±.005 | .070±.003 | 7.65±0.13 | 1.78±0.08 | 5/16 | 1/16 | 7/16 |

| -12 | .364±.005 | .070±.003 | 9.25±0.13 | 1.78±0.08 | 3/8 | 1/16 | 1/2 |

| -13 | .426±.005 | .070±.003 | 10.82±0.13 | 1.78±0.08 | 7/16 | 1/16 | 9/16 |

| -14 | .489±.005 | .070±.003 | 12.42±0.13 | 1.78±0.08 | 1/2 | 1/16 | 5/8 |

| -15 | .551±.007 | .070±.003 | 14.00±0.18 | 1.78±0.08 | 9/16 | 1/16 | 11/16 |

| -16 | .614±.009 | .070±.003 | 15.60±0.23 | 1.78±0.08 | 5/8 | 1/16 | 3/4 |

| -17 | .676±.009 | .070±.003 | 17.17±0.23 | 1.78±0.08 | 11/16 | 1/16 | 13/16 |

| -18 | .739±.009 | .070±.003 | 18.77±0.23 | 1.78±0.08 | 3/4 | 1/16 | 7/8 |

| -19 | .801±.009 | .070±.003 | 20.35±0.23 | 1.78±0.08 | 13/16 | 1/16 | 15/16 |

| -20 | .864±.009 | .070±.003 | 21.95±0.23 | 1.78±0.08 | 7/8 | 1/16 | 1 |

| -21 | .926±.009 | .070±.003 | 23.52±0.23 | 1.78±0.08 | 15/16 | 1/16 | 1-1/16 |

| -22 | .989±.010 | .070±.003 | 25.12±0.25 | 1.78±0.08 | 1 | 1/16 | 1-1/8 |

| -23 | 1.051±.010 | .070±.003 | 26.70±0.25 | 1.78±0.08 | 1-1/16 | 1/16 | 1-3/16 |

| -24 | 1.114±.010 | .070±.003 | 28.30±0.25 | 1.78±0.08 | 1-1/8 | 1/16 | 1-1/4 |

| -25 | 1.176±.011 | .070±.003 | 29.87±0.28 | 1.78±0.08 | 1-3/16 | 1/16 | 1-5/16 |

| -26 | 1.239±.011 | .070±.003 | 31.47±0.28 | 1.78±0.08 | 1-1/4 | 1/16 | 1-3/8 |

| -27 | 1.301±.011 | .070±.003 | 33.05±0.28 | 1.78±0.08 | 1-5/16 | 1/16 | 1-7/16 |

| -28 | 1.364±.013 | .070±.003 | 34.65±0.33 | 1.78±0.08 | 1-3/8 | 1/16 | 1-1/2 |

| -29 | 1.489±.013 | .070±.003 | 37.82±0.33 | 1.78±0.08 | 1-1/2 | 1/16 | 1-5/8 |

| -30 | 1.614±.013 | .070±.003 | 41.00±0.33 | 1.78±0.08 | 1-5/8 | 1/16 | 1-3/4 |

| -31 | 1.739±.015 | .070±.003 | 44.17±0.38 | 1.78±0.08 | 1-3/4 | 1/16 | 1-7/8 |

| -32 | 1.864±.015 | .070±.003 | 47.35±0.38 | 1.78±0.08 | 1-7/8 | 1/16 | 2 |

| -33 | 1.989±.018 | .070±.003 | 50.52±0.46 | 1.78±0.08 | 2 | 1/16 | 2-1/8 |

| -34 | 2.114±.018 | .070±.003 | 53.70±0.46 | 1.78±0.08 | 2-1/8 | 1/16 | 2-1/4 |

| -35 | 2.239±.018 | .070±.003 | 56.87±0.46 | 1.78±0.08 | 2-1/4 | 1/16 | 2-3/8 |

| -36 | 2.364±.018 | .070±.003 | 60.05±0.46 | 1.78±0.08 | 2-3/8 | 1/16 | 2-1/2 |

| -37 | 2.489±.018 | .070±.003 | 63.22±0.46 | 1.78±0.08 | 2-1/2 | 1/16 | 2-5/8 |

| -38 | 2.614±.020 | .070±.003 | 66.40±0.51 | 1.78±0.08 | 2-5/8 | 1/16 | 2-3/4 |

| -39 | 2.739±.020 | .070±.003 | 69.57±0.51 | 1.78±0.08 | 2-3/4 | 1/16 | 2-7/8 |

| -40 | 2.864±.020 | .070±.003 | 72.75±0.51 | 1.78±0.08 | 2-7/8 | 1/16 | 3 |

| -41 | 2.989±.024 | .070±.003 | 75.92±0.61 | 1.78±0.08 | 3 | 1/16 | 3-1/8 |

| -42 | 3.239±.024 | .070±.003 | 82.27±0.61 | 1.78±0.08 | 3-1/4 | 1/16 | 3-3/8 |

| -43 | 3.489±.024 | .070±.003 | 88.62±0.61 | 1.78±0.08 | 3-1/2 | 1/16 | 3-5/8 |

| -44 | 3.739±.027 | .070±.003 | 94.97±0.69 | 1.78±0.08 | 3-3/4 | 1/16 | 3-7/8 |

| -45 | 3.989±.027 | .070±.003 | 101.32±0.69 | 1.78±0.08 | 4 | 1/16 | 4-1/8 |

| -46 | 4.239±.030 | .070±.003 | 107.67±0.76 | 1.78±0.08 | 4-1/4 | 1/16 | 4-3/8 |

| -47 | 4.489±.030 | .070±.003 | 114.02±0.76 | 1.78±0.08 | 4-1/2 | 1/16 | 4-5/8 |

| -48 | 4.739±.030 | .070±.003 | 120.37±0.76 | 1.78±0.08 | 4-3/4 | 1/16 | 4-7/8 |

| -49 | 4.989±.037 | .070±.003 | 126.72±0.94 | 1.78±0.08 | 5 | 1/16 | 5-1/8 |

| -50 | 5.239±.037 | .070±.003 | 133.07±0.94 | 1.78±0.08 | 5-1/4 | 1/16 | 5-3/8 |

| AS568A-Dash # | Actual I.D. Inches | Actual C.S. Inches | Actual I.D. Millimeters | Actual C.S. Millimeters | Nominal Reference I.D. | Nominal Reference C.S. | Nominal Reference O.D. |

|---|---|---|---|---|---|---|---|

| -102 | .049±.005 | .103±.003 | 1.24±0.13 | 2.62±0.08 | 1/16 | 3/32 | 1/4 |

| -103 | .081±.005 | .103±.003 | 2.06±0.13 | 2.62±0.08 | 3/32 | 3/32 | 9/32 |

| -104 | .112±.005 | .103±.003 | 2.84±0.13 | 2.62±0.08 | 1/8 | 3/32 | 5/16 |

| -105 | .143±.005 | .103±.003 | 3.63±0.13 | 2.62±0.08 | 5/32 | 3/32 | 11/32 |

| -106 | .174±.005 | .103±.003 | 4.42±0.13 | 2.62±0.08 | 3/16 | 3/32 | 3/8 |

| -107 | .206±.005 | .103±.003 | 5.23±0.13 | 2.62±0.08 | 7/32 | 3/32 | 13/32 |

| -108 | .237±.005 | .103±.003 | 6.02±0.13 | 2.62±0.08 | 1/4 | 3/32 | 7/16 |

| -109 | .299±.005 | .103±.003 | 7.59±0.13 | 2.62±0.08 | 5/16 | 3/32 | 1/2 |

| -110 | .362±.005 | .103±.003 | 9.19±0.13 | 2.62±0.08 | 3/8 | 3/32 | 9/16 |

| -111 | .424±.005 | .103±.003 | 10.77±0.13 | 2.62±0.08 | 7/16 | 3/32 | 5/8 |

| -112 | .487±.005 | .103±.003 | 12.37±0.13 | 2.62±0.08 | 1/2 | 3/32 | 11/16 |

| -113 | .549±.007 | .103±.003 | 13.94±0.18 | 2.62±0.08 | 9/16 | 3/32 | 3/4 |

| -114 | .612±.009 | .103±.003 | 15.54±0.23 | 2.62±0.08 | 5/8 | 3/32 | 13/16 |

| -115 | .674±.009 | .103±.003 | 17.12±0.23 | 2.62±0.08 | 11/16 | 3/32 | 7/8 |

| -116 | .737±.009 | .103±.003 | 18.72±0.23 | 2.62±0.08 | 3/4 | 3/32 | 15/16 |

| -117 | .799±.010 | .103±.003 | 20.30±0.25 | 2.62±0.08 | 13/16 | 3/32 | 1 |

| -118 | .862±.010 | .103±.003 | 21.89±0.25 | 2.62±0.08 | 7/8 | 3/32 | 1-1/16 |

| -119 | .924±.010 | .103±.003 | 23.47±0.25 | 2.62±0.08 | 15/16 | 3/32 | 1-1/8 |

| -120 | .987±.010 | .103±.003 | 25.07±0.25 | 2.62±0.08 | 1 | 3/32 | 1-3/16 |

| -121 | 1.049±.010 | .103±.003 | 26.64±0.25 | 2.62±0.08 | 1-1/16 | 3/32 | 1-1/4 |

| -122 | 1.112±.010 | .103±.003 | 28.24±0.25 | 2.62±0.08 | 1-1/8 | 3/32 | 1-5/16 |

| -123 | 1.174±.012 | .103±.003 | 29.82±0.30 | 2.62±0.08 | 1-3/16 | 3/32 | 1-3/8 |

| -124 | 1.237±.012 | .103±.003 | 31.42±0.30 | 2.62±0.08 | 1-1/4 | 3/32 | 1-7/16 |

| -125 | 1.299±.012 | .103±.003 | 32.99±0.30 | 2.62±0.08 | 1-5/16 | 3/32 | 1-1/2 |

| -126 | 1.362±.012 | .103±.003 | 34.59±0.30 | 2.62±0.08 | 1-3/8 | 3/32 | 1-9/16 |

| -127 | 1.424±.012 | .103±.003 | 36.17±0.30 | 2.62±0.08 | 1-7/16 | 3/32 | 1-5/8 |

| -128 | 1.487±.012 | .103±.003 | 37.77±0.30 | 2.62±0.08 | 1-1/2 | 3/32 | 1-11/16 |

| -129 | 1.549±.015 | .103±.003 | 39.34±0.38 | 2.62±0.08 | 1-9/16 | 3/32 | 1-3/4 |

| -130 | 1.612±.015 | .103±.003 | 40.94±0.38 | 2.62±0.08 | 1-5/8 | 3/32 | 1-13/16 |

| -131 | 1.674±.015 | .103±.003 | 42.52±0.38 | 2.62±0.08 | 1-11/16 | 3/32 | 1-7/8 |

| -132 | 1.737±.015 | .103±.003 | 44.12±0.38 | 2.62±0.08 | 1-3/4 | 3/32 | 1-15/16 |

| -133 | 1.799±.015 | .103±.003 | 45.69±0.38 | 2.62±0.08 | 1-13/16 | 3/32 | 2 |

| -134 | 1.862±.015 | .103±.003 | 47.30±0.38 | 2.62±0.08 | 1-7/8 | 3/32 | 2-1/16 |

| -135 | 1.925±.017 | .103±.003 | 48.90±0.43 | 2.62±0.08 | 1-15/16 | 3/32 | 2-1/8 |

| -136 | 1.987±.017 | .103±.003 | 50.47±0.43 | 2.62±0.08 | 2 | 3/32 | 2-3/16 |

| -137 | 2.050±.017 | .103±.003 | 52.07±0.43 | 2.62±0.08 | 2-1/16 | 3/32 | 2-1/4 |

| -138 | 2.112±.017 | .103±.003 | 53.64±0.43 | 2.62±0.08 | 2-1/8 | 3/32 | 2-5/16 |

| -139 | 2.175±.017 | .103±.003 | 55.25±0.43 | 2.62±0.08 | 2-3/16 | 3/32 | 2-3/8 |

| -140 | 2.237±.017 | .103±.003 | 56.82±0.43 | 2.62±0.08 | 2-1/4 | 3/32 | 2-7/16 |

| -141 | 2.300±.020 | .103±.003 | 58.42±0.51 | 2.62±0.08 | 2-5/16 | 3/32 | 2-1/2 |

| -142 | 2.362±.020 | .103±.003 | 59.99±0.51 | 2.62±0.08 | 2-3/8 | 3/32 | 2-9/16 |

| -143 | 2.425±.020 | .103±.003 | 61.60±0.51 | 2.62±0.08 | 2-7/16 | 3/32 | 2-5/8 |

| -144 | 2.487±.020 | .103±.003 | 63.17±0.51 | 2.62±0.08 | 2-1/2 | 3/32 | 2-11/16 |

| -145 | 2.550±.020 | .103±.003 | 64.77±0.51 | 2.62±0.08 | 2-9/16 | 3/32 | 2-3/4 |

| -146 | 2.612±.020 | .103±.003 | 66.34±0.51 | 2.62±0.08 | 2-5/8 | 3/32 | 2-13/16 |

| -147 | 2.675±.022 | .103±.003 | 67.95±0.56 | 2.62±0.08 | 2-11/16 | 3/32 | 2-7/8 |

| -148 | 2.737±.022 | .103±.003 | 69.52±0.56 | 2.62±0.08 | 2-3/4 | 3/32 | 2-15/16 |

| -149 | 2.800±.022 | .103±.003 | 71.12±0.56 | 2.62±0.08 | 2-13/16 | 3/32 | 3 |

| -150 | 2.862±.022 | .103±.003 | 72.69±0.56 | 2.62±0.08 | 2-7/8 | 3/32 | 3-1/16 |

| -151 | 2.987±.024 | .103±.003 | 75.87±0.61 | 2.62±0.08 | 3 | 3/32 | 3-3/16 |

| -152 | 3.237±.024 | .103±.003 | 82.22±0.61 | 2.62±0.08 | 3-1/4 | 3/32 | 3-7/16 |

| -153 | 3.487±.024 | .103±.003 | 88.57±0.61 | 2.62±0.08 | 3-1/2 | 3/32 | 3-11/16 |

| -154 | 3.737±.028 | .103±.003 | 94.92±0.71 | 2.62±0.08 | 3-3/4 | 3/32 | 3-15/16 |

| -155 | 3.987±.028 | .103±.003 | 101.27±0.71 | 2.62±0.08 | 4 | 3/32 | 4-3/16 |

| -156 | 4.237±.030 | .103±.003 | 107.62±0.76 | 2.62±0.08 | 4-1/4 | 3/32 | 4-7/16 |

| -157 | 4.487±.030 | .103±.003 | 113.97±0.76 | 2.62±0.08 | 4-1/2 | 3/32 | 4-11/16 |

| -158 | 4.737±.030 | .103±.003 | 120.32±0.76 | 2.62±0.08 | 4-3/4 | 3/32 | 4-15/16 |

| -159 | 4.987±.035 | .103±.003 | 126.67±0.89 | 2.62±0.08 | 5 | 3/32 | 5-3/16 |

| -160 | 5.237±.035 | .103±.003 | 133.02±0.89 | 2.62±0.08 | 5-1/4 | 3/32 | 5-7/16 |

| -161 | 5.487±.035 | .103±.003 | 139.37±0.89 | 2.62±0.08 | 5-1/2 | 3/32 | 5-11/16 |

| -162 | 5.737±.035 | .103±.003 | 145.72±0.89 | 2.62±0.08 | 5-3/4 | 3/32 | 5-15/16 |

| -163 | 5.987±.035 | .103±.003 | 152.07±0.89 | 2.62±0.08 | 6 | 3/32 | 6-3/16 |

| -164 | 6.237±.040 | .103±.003 | 158.42±1.02 | 2.62±0.08 | 6-1/4 | 3/32 | 6-7/16 |

| -165 | 6.487±.040 | .103±.003 | 164.77±1.02 | 2.62±0.08 | 6-1/2 | 3/32 | 6-11/16 |

| -166 | 6.737±.040 | .103±.003 | 171.12±1.02 | 2.62±0.08 | 6-3/4 | 3/32 | 6-15/16 |

| -167 | 6.987±.040 | .103±.003 | 177.47±1.02 | 2.62±0.08 | 7 | 3/32 | 7-3/16 |

| -168 | 7.237±.045 | .103±.003 | 183.82±1.14 | 2.62±0.08 | 7-1/4 | 3/32 | 7-7/16 |

| -169 | 7.487±.045 | .103±.003 | 190.17±1.14 | 2.62±0.08 | 7-1/2 | 3/32 | 7-11/16 |

| -170 | 7.737±.045 | .103±.003 | 196.52±1.14 | 2.62±0.08 | 7-3/4 | 3/32 | 7-15/16 |

| -171 | 7.987±.045 | .103±.003 | 202.87±1.14 | 2.62±0.08 | 8 | 3/32 | 8-3/16 |

| -172 | 8.237±.050 | .103±.003 | 209.22±1.27 | 2.62±0.08 | 8-1/4 | 3/32 | 8-7/16 |

| -173 | 8.487±.050 | .103±.003 | 215.57±1.27 | 2.62±0.08 | 8-1/2 | 3/32 | 8-11/16 |

| -174 | 8.737±.050 | .103±.003 | 221.92±1.27 | 2.62±0.08 | 8-3/4 | 3/32 | 8-15/16 |

| -175 | 8.987±.050 | .103±.003 | 228.27±1.27 | 2.62±0.08 | 9 | 3/32 | 9-3/16 |

| -176 | 9.237±.055 | .103±.003 | 234.62±1.40 | 2.62±0.08 | 9-1/4 | 3/32 | 9-7/16 |

| -177 | 9.487±.055 | .103±.003 | 240.97±1.40 | 2.62±0.08 | 9-1/2 | 3/32 | 9-11/16 |

| -178 | 9.737±.055 | .103±.003 | 247.32±1.40 | 2.62±0.08 | 9-3/4 | 3/32 | 9-15/16 |

| AS568A-Dash # | Actual I.D. Inches | Actual C.S. Inches | Actual I.D. Millimeters | Actual C.S. Millimeters | Nominal Reference I.D. | Nominal Reference C.S. | Nominal Reference O.D. |

|---|---|---|---|---|---|---|---|

| -201 | .171±.005 | .139±.004 | 4.34±0.13 | 3.53±0.10 | 3/16 | 1/8 | 7/16 |

| -202 | .234±.005 | .139±.004 | 5.94±0.13 | 3.53±0.10 | 1/4 | 1/8 | 1/2 |

| -203 | .296±.005 | .139±.004 | 7.52±0.13 | 3.53±0.10 | 5/16 | 1/8 | 9/16 |

| -204 | .359±.005 | .139±.004 | 9.12±0.13 | 3.53±0.10 | 3/8 | 1/8 | 5/8 |

| -205 | .421±.005 | .139±.004 | 10.69±0.13 | 3.53±0.10 | 7/16 | 1/8 | 11/16 |

| -206 | .484±.005 | .139±.004 | 12.29±0.13 | 3.53±0.10 | 1/2 | 1/8 | 3/4 |

| -207 | .546±.007 | .139±.004 | 13.87±0.17 | 3.53±0.10 | 9/16 | 1/8 | 13/16 |

| -208 | .609±.009 | .139±.004 | 15.47±0.23 | 3.53±0.10 | 5/8 | 1/8 | 7/8 |

| -209 | .671±.009 | .139±.004 | 17.04±0.23 | 3.53±0.10 | 11/16 | 1/8 | 15/16 |

| -210 | .734±.010 | .139±.004 | 18.64±0.25 | 3.53±0.10 | 3/4 | 1/8 | 1 |

| -211 | .796±.010 | .139±.004 | 20.22±0.25 | 3.53±0.10 | 13/16 | 1/8 | 1-1/16 |

| -212 | .859±.010 | .139±.004 | 21.82±0.25 | 3.53±0.10 | 7/8 | 1/8 | 1-1/8 |

| -213 | .921±.010 | .139±.004 | 23.39±0.25 | 3.53±0.10 | 15/16 | 1/8 | 1-3/16 |

| -214 | .984±.010 | .139±.004 | 25.00±0.25 | 3.53±0.10 | 1 | 1/8 | 1-1/4 |

| -215 | 1.046±.010 | .139±.004 | 26.57±0.25 | 3.53±0.10 | 1-1/16 | 1/8 | 1-5/16 |

| -216 | 1.109±.012 | .139±.004 | 28.17±0.30 | 3.53±0.10 | 1-1/8 | 1/8 | 1-3/8 |

| -217 | 1.171±.012 | .139±.004 | 29.74±0.30 | 3.53±0.10 | 1-3/16 | 1/8 | 1-7/16 |

| -218 | 1.234±.012 | .139±.004 | 31.34±0.30 | 3.53±0.10 | 1-1/4 | 1/8 | 1-1/2 |

| -219 | 1.296±.012 | .139±.004 | 32.92±0.30 | 3.53±0.10 | 1-5/16 | 1/8 | 1-9/16 |

| -220 | 1.359±.012 | .139±.004 | 34.52±0.30 | 3.53±0.10 | 1-3/8 | 1/8 | 1-5/8 |

| -221 | 1.421±.012 | .139±.004 | 36.09±0.30 | 3.53±0.10 | 1-7/16 | 1/8 | 1-11/16 |

| -222 | 1.484±.015 | .139±.004 | 37.69±0.38 | 3.53±0.10 | 1-1/2 | 1/8 | 1-3/4 |

| -223 | 1.609±.015 | .139±.004 | 40.87±0.38 | 3.53±0.10 | 1-5/8 | 1/8 | 1-7/8 |

| -224 | 1.734±.015 | .139±.004 | 44.04±0.38 | 3.53±0.10 | 1-3/4 | 1/8 | 2 |

| -225 | 1.859±.018 | .139±.004 | 47.22±0.46 | 3.53±0.10 | 1-7/8 | 1/8 | 2-1/8 |

| -226 | 1.984±.018 | .139±.004 | 50.39±0.46 | 3.53±0.10 | 2 | 1/8 | 2-1/4 |

| -227 | 2.109±.018 | .139±.004 | 53.57±0.46 | 3.53±0.10 | 2-1/8 | 1/8 | 2-3/8 |

| -228 | 2.234±.020 | .139±.004 | 56.74±0.50 | 3.53±0.10 | 2-1/4 | 1/8 | 2-1/2 |

| -229 | 2.359±.020 | .139±.004 | 59.92±0.50 | 3.53±0.10 | 2-3/8 | 1/8 | 2-5/8 |

| -230 | 2.484±.020 | .139±.004 | 63.09±0.50 | 3.53±0.10 | 2-1/2 | 1/8 | 2-3/4 |

| -231 | 2.609±.020 | .139±.004 | 66.27±0.50 | 3.53±0.10 | 2-5/8 | 1/8 | 2-7/8 |

| -232 | 2.734±.024 | .139±.004 | 69.44±0.61 | 3.53±0.10 | 2-3/4 | 1/8 | 3 |

| -233 | 2.859±.024 | .139±.004 | 72.62±0.61 | 3.53±0.10 | 2-7/8 | 1/8 | 3-1/8 |

| -234 | 2.984±.024 | .139±.004 | 75.79±0.61 | 3.53±0.10 | 3 | 1/8 | 3-1/4 |

| -235 | 3.109±.024 | .139±.004 | 78.97±0.61 | 3.53±0.10 | 3-1/8 | 1/8 | 3-3/8 |

| -236 | 3.234±.024 | .139±.004 | 82.14±0.61 | 3.53±0.10 | 3-1/4 | 1/8 | 3-1/2 |

| -237 | 3.359±.024 | .139±.004 | 85.32±0.61 | 3.53±0.10 | 3-3/8 | 1/8 | 3-5/8 |

| -238 | 3.484±.024 | .139±.004 | 88.49±0.61 | 3.53±0.10 | 3-1/2 | 1/8 | 3-3/4 |

| -239 | 3.609±.028 | .139±.004 | 91.67±0.71 | 3.53±0.10 | 3-5/8 | 1/8 | 3-7/8 |

| -240 | 3.734±.028 | .139±.004 | 94.84±0.71 | 3.53±0.10 | 3-3/4 | 1/8 | 4 |

| -241 | 3.859±.028 | .139±.004 | 98.02±0.71 | 3.53±0.10 | 3-7/8 | 1/8 | 4-1/8 |

| -242 | 3.984±.028 | .139±.004 | 101.19±0.71 | 3.53±0.10 | 4 | 1/8 | 4-1/4 |

| -243 | 4.109±.028 | .139±.004 | 104.37±0.71 | 3.53±0.10 | 4-1/8 | 1/8 | 4-3/8 |

| -244 | 4.234±.030 | .139±.004 | 107.54±0.76 | 3.53±0.10 | 4-1/4 | 1/8 | 4-1/2 |

| -245 | 4.359±.030 | .139±.004 | 110.72±0.76 | 3.53±0.10 | 4-3/8 | 1/8 | 4-5/8 |

| -246 | 4.484±.030 | .139±.004 | 113.89±0.76 | 3.53±0.10 | 4-1/2 | 1/8 | 4-3/4 |

| -247 | 4.609±.030 | .139±.004 | 117.07±0.76 | 3.53±0.10 | 4-5/8 | 1/8 | 4-7/8 |

| -248 | 4.734±.030 | .139±.004 | 120.24±0.76 | 3.53±0.10 | 4-3/4 | 1/8 | 5 |

| -249 | 4.859±.035 | .139±.004 | 123.42±0.89 | 3.53±0.10 | 4-7/8 | 1/8 | 5-1/8 |

| -250 | 4.984±.035 | .139±.004 | 126.59±0.89 | 3.53±0.10 | 5 | 1/8 | 5-1/4 |

| -251 | 5.109±.035 | .139±.004 | 129.77±0.89 | 3.53±0.10 | 5-1/8 | 1/8 | 5-3/8 |

| -252 | 5.234±.035 | .139±.004 | 132.94±0.89 | 3.53±0.10 | 5-1/4 | 1/8 | 5-1/2 |

| -253 | 5.359±.035 | .139±.004 | 136.12±0.89 | 3.53±0.10 | 5-3/8 | 1/8 | 5-5/8 |

| -254 | 5.484±.035 | .139±.004 | 139.29±0.89 | 3.53±0.10 | 5-1/2 | 1/8 | 5-3/4 |

| -255 | 5.609±.035 | .139±.004 | 142.47±0.89 | 3.53±0.10 | 5-5/8 | 1/8 | 5-7/8 |

| -256 | 5.734±.035 | .139±.004 | 145.65±0.89 | 3.53±0.10 | 5-3/4 | 1/8 | 6 |

| -257 | 5.859±.035 | .139±.004 | 148.82±0.89 | 3.53±0.10 | 5-7/8 | 1/8 | 6-1/8 |

| -258 | 5.984±.035 | .139±.004 | 151.99±0.89 | 3.53±0.10 | 6 | 1/8 | 6-1/4 |

| -259 | 6.234±.040 | .139±.004 | 158.34±1.02 | 3.53±0.10 | 6-1/4 | 1/8 | 6-1/2 |

| -260 | 6.484±.040 | .139±.004 | 164.69±1.02 | 3.53±0.10 | 6-1/2 | 1/8 | 6-3/4 |

| -261 | 6.734±.040 | .139±.004 | 171.04±1.02 | 3.53±0.10 | 6-3/4 | 1/8 | 7 |

| -262 | 6.984±.040 | .139±.004 | 177.39±1.02 | 3.53±0.10 | 7 | 1/8 | 7-1/4 |

| -263 | 7.234±.045 | .139±.004 | 183.74±1.14 | 3.53±0.10 | 7-1/4 | 1/8 | 7-1/2 |

| -264 | 7.484±.045 | .139±.004 | 190.09±1.14 | 3.53±0.10 | 7-1/2 | 1/8 | 7-3/4 |

| -265 | 7.734±.045 | .139±.004 | 196.44±1.14 | 3.53±0.10 | 7-3/4 | 1/8 | 8 |

| -266 | 7.984±.045 | .139±.004 | 202.79±1.14 | 3.53±0.10 | 8 | 1/8 | 8-1/4 |

| -267 | 8.234±.050 | .139±.004 | 209.14±1.27 | 3.53±0.10 | 8-1/4 | 1/8 | 8-1/2 |

| -268 | 8.484±.050 | .139±.004 | 215.49±1.27 | 3.53±0.10 | 8-1/2 | 1/8 | 8-3/4 |

| -269 | 8.734±.050 | .139±.004 | 221.84±1.27 | 3.53±0.10 | 8-3/4 | 1/8 | 9 |

| -270 | 8.984±.050 | .139±.004 | 228.19±1.27 | 3.53±0.10 | 9 | 1/8 | 9-1/4 |

| -271 | 9.234±.055 | .139±.004 | 234.54±1.40 | 3.53±0.10 | 9-1/4 | 1/8 | 9-1/2 |

| -272 | 9.484±.055 | .139±.004 | 240.89±1.40 | 3.53±0.10 | 9-1/2 | 1/8 | 9-3/4 |

| -273 | 9.734±.055 | .139±.004 | 247.24±1.40 | 3.53±0.10 | 9-3/4 | 1/8 | 10 |

| -274 | 9.984±.055 | .139±.004 | 253.59±1.40 | 3.53±0.10 | 10 | 1/8 | 10-1/4 |

| -275 | 10.484±.065 | .139±.004 | 266.29±1.40 | 3.53±0.10 | 10-1/2 | 1/8 | 10-3/4 |

| -276 | 10.984±.065 | .139±.004 | 278.99±1.65 | 3.53±0.10 | 11 | 1/8 | 11-1/4 |

| -277 | 11.484±.065 | .139±.004 | 291.69±1.65 | 3.53±0.10 | 11-1/2 | 1/8 | 11-3/4 |

| -278 | 11.984±.065 | .139±.004 | 304.39±1.65 | 3.53±0.10 | 12 | 1/8 | 12-1/4 |

| -279 | 12.984±.065 | .139±.004 | 329.79±1.65 | 3.53±0.10 | 13 | 1/8 | 13-1/4 |

| -280 | 13.984±.065 | .139±.004 | 355.19±1.65 | 3.53±0.10 | 14 | 1/8 | 14-1/4 |

| -281 | 14.984±.065 | .139±.004 | 380.59±1.65 | 3.53±0.10 | 15 | 1/8 | 15-1/4 |

| -282 | 15.955±.075 | .139±.004 | 405.26±1.91 | 3.53±0.10 | 16 | 1/8 | 16-1/4 |

| -283 | 16.955±.080 | .139±.004 | 430.66±2.03 | 3.53±0.10 | 17 | 1/8 | 17-1/4 |

| -284 | 17.955±.085 | .139±.004 | 456.06±2.16 | 3.53±0.10 | 18 | 1/8 | 18-1/4 |

| AS568A-Dash # | Actual I.D. Inches | Actual C.S. Inches | Actual I.D. Millimeters | Actual C.S. Millimeters | Nominal Reference I.D. | Nominal Reference C.S. | Nominal Reference O.D. |

|---|---|---|---|---|---|---|---|

| -309 | .412±.005 | .210±.005 | 10.46±0.13 | 5.33±0.13 | 7/16 | 3/16 | 13/16 |

| -310 | .475±.005 | .210±.005 | 12.07±0.13 | 5.33±0.13 | 1/2 | 3/16 | 7/8 |

| -311 | .537±.007 | .210±.005 | 13.64±0.18 | 5.33±0.13 | 9/16 | 3/16 | 15-16 |

| -312 | .600±.009 | .210±.005 | 15.24±0.23 | 5.33±0.13 | 5/8 | 3/16 | 1 |

| -313 | .662±.009 | .210±.005 | 16.81±0.23 | 5.33±0.13 | 11-16 | 3/16 | 1-1/16 |

| -314 | .725±.010 | .210±.005 | 18.42±0.25 | 5.33±0.13 | 3/4 | 3/16 | 1-1/8 |

| -315 | .787±.010 | .210±.005 | 19.99±0.25 | 5.33±0.13 | 13/16 | 3/16 | 1-3/6 |

| -316 | .850±.010 | .210±.005 | 21.59±0.25 | 5.33±0.13 | 7/8 | 3/16 | 1-1/4 |

| -317 | .912±.010 | .210±.005 | 23.16±0.25 | 5.33±0.13 | 15/16 | 3/16 | 1-5/16 |

| -318 | .975±.010 | .210±.005 | 24.77±0.25 | 5.33±0.13 | 1 | 3/16 | 1-3/8 |

| -319 | 1.037±.010 | .210±.005 | 26.34±0.25 | 5.33±0.13 | 1-1/16 | 3/16 | 1-7/16 |

| -320 | 1.100±.012 | .210±.005 | 27.94±0.30 | 5.33±0.13 | 1-1/8 | 3/16 | 1-1/2 |

| -321 | 1.162±.012 | .210±.005 | 29.51±0.30 | 5.33±0.13 | 1-3/16 | 3/16 | 1-9/16 |

| -322 | 1.225±.012 | .210±.005 | 31.12±0.30 | 5.33±0.13 | 1-1/4 | 3/16 | 1-5/8 |

| -323 | 1.287±.012 | .210±.005 | 32.69±0.30 | 5.33±0.13 | 1-5/16 | 3/16 | 1-11/16 |

| -324 | 1.350±.012 | .210±.005 | 34.29±0.30 | 5.33±0.13 | 1-3/8 | 3/16 | 1-3/4 |

| -325 | 1.475±.015 | .210±.005 | 37.47±0.38 | 5.33±0.13 | 1-1/2 | 3/16 | 1-7/8 |

| -326 | 1.600±.015 | .210±.005 | 40.64±0.38 | 5.33±0.13 | 1-5/8 | 3/16 | 2 |

| -327 | 1.725±.015 | .210±.005 | 43.82±0.38 | 5.33±0.13 | 1-3/4 | 3/16 | 2-1/8 |

| -328 | 1.850±.015 | .210±.005 | 46.99±0.38 | 5.33±0.13 | 1-7/8 | 3/16 | 2-1/4 |

| -329 | 1.975±.018 | .210±.005 | 50.17±0.46 | 5.33±0.13 | 2 | 3/16 | 2-3/8 |

| -330 | 2.100±.018 | .210±.005 | 53.34±0.46 | 5.33±0.13 | 2-1/8 | 3/16 | 2-1/2 |

| -331 | 2.225±.018 | .210±.005 | 56.52±0.46 | 5.33±0.13 | 2-1/4 | 3/16 | 2-5/8 |

| -332 | 2.350±.018 | .210±.005 | 59.69±0.46 | 5.33±0.13 | 2-3/8 | 3/16 | 2-3/4 |

| -333 | 2.475±.020 | .210±.005 | 62.87±0.51 | 5.33±0.13 | 2-1/2 | 3/16 | 2-7/8 |

| -334 | 2.600±.020 | .210±.005 | 66.04±0.51 | 5.33±0.13 | 2-5/8 | 3/16 | 3 |

| -335 | 2.725±.020 | .210±.005 | 69.22±0.51 | 5.33±0.13 | 2-3/4 | 3/16 | 3-1/8 |

| -336 | 2.850±.020 | .210±.005 | 72.39±0.51 | 5.33±0.13 | 2-7/8 | 3/16 | 3-1/4 |

| -337 | 2.975±.024 | .210±.005 | 75.57±0.61 | 5.33±0.13 | 3 | 3/16 | 3-3/8 |

| -338 | 3.100±.024 | .210±.005 | 78.74±0.61 | 5.33±0.13 | 3-1/8 | 3/16 | 3-1/2 |

| -339 | 3.225±.024 | .210±.005 | 91.92±0.61 | 5.33±0.13 | 3-1/4 | 3/16 | 3-5/8 |

| -340 | 3.350±.024 | .210±.005 | 85.09±0.61 | 5.33±0.13 | 3-3/8 | 3/16 | 3-3/4 |

| -341 | 3.475±.024 | .210±.005 | 88.27±0.61 | 5.33±0.13 | 3-1/2 | 3/16 | 3-7/8 |

| -342 | 3.600±.028 | .210±.005 | 91.44±0.71 | 5.33±0.13 | 3-5/8 | 3/16 | 4 |

| -343 | 3.725±.028 | .210±.005 | 94.62±0.71 | 5.33±0.13 | 3-3/4 | 3/16 | 4-1/8 |

| -344 | 3.850±.028 | .210±.005 | 97.79±0.71 | 5.33±0.13 | 3-7/8 | 3/16 | 4-1/4 |

| -345 | 3.975±.028 | .210±.005 | 100.97±0.71 | 5.33±0.13 | 4 | 3/16 | 4-3/8 |

| -346 | 4.100±.028 | .210±.005 | 104.14±0.71 | 5.33±0.13 | 4-1/8 | 3/16 | 4-1/2 |

| -347 | 4.225±.030 | .210±.005 | 107.32±0.76 | 5.33±0.13 | 4-1/4 | 3/16 | 4-5/8 |

| -348 | 4.350±.030 | .210±.005 | 110.49±0.76 | 5.33±0.13 | 4-3/8 | 3/16 | 4-3/4 |

| -349 | 4.475±.030 | .210±.005 | 113.67±0.76 | 5.33±0.13 | 4-1/2 | 3/16 | 4-7/8 |

| -350 | 4.600±.030 | .210±.005 | 116.84±0.76 | 5.33±0.13 | 4-5/8 | 3/16 | 5 |

| -351 | 4.725±.030 | .210±.005 | 120.02±0.76 | 5.33±0.13 | 4-3/4 | 3/16 | 5-1/8 |

| -352 | 4.850±.030 | .210±.005 | 123.19±0.76 | 5.33±0.13 | 4-7/8 | 3/16 | 5-1/4 |

| -353 | 4.975±.037 | .210±.005 | 126.37±0.94 | 5.33±0.13 | 5 | 3/16 | 5-3/8 |

| -354 | 5.100±.037 | .210±.005 | 129.54±0.94 | 5.33±0.13 | 5-1/8 | 3/16 | 5-1/2 |

| -355 | 5.225±.037 | .210±.005 | 132.72±0.94 | 5.33±0.13 | 5-1/4 | 3/16 | 5-5/8 |

| -356 | 5.350±.037 | .210±.005 | 135.89±0.94 | 5.33±0.13 | 5-3/8 | 3/16 | 5-3/4 |

| -357 | 5.475±.037 | .210±.005 | 139.07±0.94 | 5.33±0.13 | 5-1/2 | 3/16 | 5-7/8 |

| -358 | 5.600±.037 | .210±.005 | 142.24±0.94 | 5.33±0.13 | 5-5/8 | 3/16 | 6 |

| -359 | 5.725±.037 | .210±.005 | 145.42±0.94 | 5.33±0.13 | 5-3/4 | 3/16 | 6-1/8 |

| -360 | 5.850±.037 | .210±.005 | 148.59±0.94 | 5.33±0.13 | 5-7/8 | 3/16 | 6-1/4 |

| -361 | 5.975±.037 | .210±.005 | 151.77±0.94 | 5.33±0.13 | 6 | 3/16 | 6-3/8 |

| -362 | 6.225±.040 | .210±.005 | 158.12±1.02 | 5.33±0.13 | 6-1/4 | 3/16 | 6-5/8 |

| -363 | 6.475±.040 | .210±.005 | 164.47±1.02 | 5.33±0.13 | 6-1/2 | 3/16 | 6-7/8 |

| -364 | 6.725±.040 | .210±.005 | 170.82±1.02 | 5.33±0.13 | 6-3/4 | 3/16 | 7-1/8 |

| -365 | 6.975±.040 | .210±.005 | 177.17±1.02 | 5.33±0.13 | 7 | 3/16 | 7-3/8 |

| -366 | 7.225±.045 | .210±.005 | 183.52±1.14 | 5.33±0.13 | 7-1/4 | 3/16 | 7-5/8 |

| -367 | 7.475±.045 | .210±.005 | 189.87±1.14 | 5.33±0.13 | 7-1/2 | 3/16 | 7-7/8 |

| -368 | 7.725±.045 | .210±.005 | 196.22±1.14 | 5.33±0.13 | 7-3/4 | 3/16 | 8-1/8 |

| -369 | 7.975±.045 | .210±.005 | 202.57±1.14 | 5.33±0.13 | 8 | 3/16 | 8-3/8 |

| -370 | 8.225±.050 | .210±.005 | 208.92±1.27 | 5.33±0.13 | 8-1/4 | 3/16 | 8-5/8 |

| -371 | 8.475±.050 | .210±.005 | 215.27±1.27 | 5.33±0.13 | 8-1/2 | 3/16 | 8-7/8 |

| -372 | 8.725±.050 | .210±.005 | 221.62±1.27 | 5.33±0.13 | 8-3/4 | 3/16 | 9-1/8 |

| -373 | 8.975±.050 | .210±.005 | 227.97±1.27 | 5.33±0.13 | 9 | 3/16 | 9-3/8 |

| -374 | 9.225±.055 | .210±.005 | 234.32±1.40 | 5.33±0.13 | 9-1/4 | 3/16 | 9-5/8 |

| -375 | 9.475±.055 | .210±.005 | 240.67±1.40 | 5.33±0.13 | 9-1/2 | 3/16 | 9-7/8 |

| -376 | 9.725±.055 | .210±.005 | 247.02±1.40 | 5.33±0.13 | 9-3/4 | 3/16 | 10-1/8 |

| -377 | 9.975±.055 | .210±.005 | 253.37±1.40 | 5.33±0.13 | 10 | 3/16 | 10-3/8 |

| -378 | 10.475±.060 | .210±.005 | 266.07±1.52 | 5.33±0.13 | 10-1/2 | 3/16 | 10-7/8 |

| -379 | 10.975±.060 | .210±.005 | 278.77±1.52 | 5.33±0.13 | 11 | 3/16 | 11-3/8 |

| -380 | 11.475±.065 | .210±.005 | 291.47±1.65 | 5.33±0.13 | 11-1/2 | 3/16 | 11-7/8 |

| -381 | 11.975±.065 | .210±.005 | 304.17±1.65 | 5.33±0.13 | 12 | 3/16 | 12-3/8 |

| -382 | 12.975±.065 | .210±.005 | 329.57±1.65 | 5.33±0.13 | 13 | 3/16 | 13-3/8 |

| -383 | 13.975±.070 | .210±.005 | 354.97±1.78 | 5.33±0.13 | 14 | 3/16 | 14-3/8 |

| -384 | 14.975±.070 | .210±.005 | 380.37±1.78 | 5.33±0.13 | 15 | 3/16 | 15-3/8 |

| -385 | 15.955±.075 | .210±.005 | 405.26±1.91 | 5.33±0.13 | 16 | 3/16 | 16-3/8 |

| -386 | 16.955±.080 | .210±.005 | 430.66±2.03 | 5.33±0.13 | 17 | 3/16 | 17-3/8 |

| -387 | 17.955±.085 | .210±.005 | 456.06±2.16 | 5.33±0.13 | 18 | 3/16 | 18-3/8 |

| -388 | 18.955±.090 | .210±.005 | 481.41±2.29 | 5.33±0.13 | 19 | 3/16 | 19-3/8 |

| -389 | 19.955±.095 | .210±.005 | 506.81±2.41 | 5.33±0.13 | 20 | 3/16 | 20-3/8 |

| -390 | 20.955±.095 | .210±.005 | 532.21±2.41 | 5.33±0.13 | 21 | 3/16 | 21-3/8 |

| -391 | 21.955±.100 | .210±.005 | 557.61±2.54 | 5.33±0.13 | 22 | 3/16 | 22-3/8 |

| -392 | 22.940±.105 | .210±.005 | 582.68±2.67 | 5.33±0.13 | 23 | 3/16 | 23-3/8 |

| -393 | 23.940±.110 | .210±.005 | 608.08±2.79 | 5.33±0.13 | 24 | 3/16 | 24-3/8 |

| -394 | 24.940±.115 | .210±.005 | 633.48±2.92 | 5.33±0.13 | 25 | 3/16 | 25-3/8 |

| -395 | 25.940±.120 | .210±.005 | 658.88±3.05 | 5.33±0.13 | 26 | 3/16 | 26-3/8 |

| AS568A-Dash # | Actual I.D. Inches | Actual C.S. Inches | Actual I.D. Millimeters | Actual C.S. Millimeters | Nominal Reference I.D. | Nominal Reference C.S. | Nominal Reference O.D. |

|---|---|---|---|---|---|---|---|

| -425M | 4.475±.033 | .275±.006 | 113.67±0.84 | 6.99±0.15 | 4-1/2 | 1/4 | 5 |

| -426 | 4.600±.033 | .275±.006 | 116.84±0.84 | 6.99±0.15 | 4-5/8 | 1/4 | 5-1/8 |

| -427 | 4.725±.033 | .275±.006 | 120.02±0.84 | 6.99±0.15 | 4-3/4 | 1/4 | 5-1/4 |

| -428 | 4.850±.033 | .275±.006 | 123.19±0.84 | 6.99±0.15 | 4-7/8 | 1/4 | 5-3/8 |

| -429 | 4.975±.037 | .275±.006 | 126.37±0.94 | 6.99±0.15 | 5 | 1/4 | 5-1/2 |

| -430 | 5.100±.037 | .275±.006 | 129.54±0.94 | 6.99±0.15 | 5-1/8 | 1/4 | 5-5/8 |

| -431 | 5.225±.037 | .275±.006 | 132.72±0.94 | 6.99±0.15 | 5-1/4 | 1/4 | 5-3/4 |

| -432 | 5.350±.037 | .275±.006 | 135.89±0.94 | 6.99±0.15 | 5-3/8 | 1/4 | 5-7/8 |

| -433 | 5.475±.037 | .275±.006 | 139.07±0.94 | 6.99±0.15 | 5-1/2 | 1/4 | 6 |

| -434 | 5.600±.037 | .275±.006 | 142.24±0.94 | 6.99±0.15 | 5-5/8 | 1/4 | 6-1/8 |

| -435 | 5.725±.037 | .275±.006 | 145.42±0.94 | 6.99±0.15 | 5-3/4 | 1/4 | 6-1/4 |

| -436 | 5.850±.037 | .275±.006 | 148.59±0.94 | 6.99±0.15 | 5-7/8 | 1/4 | 6-3/8 |

| -437 | 5.975±.037 | .275±.006 | 151.77±0.94 | 6.99±0.15 | 6 | 1/4 | 6-1/2 |

| -438 | 6.225±.040 | .275±.006 | 158.12±1.02 | 6.99±0.15 | 6-1/4 | 1/4 | 6-3/4 |

| -439 | 6.475±.040 | .275±.006 | 164.47±1.02 | 6.99±0.15 | 6-1/2 | 1/4 | 7 |

| -440 | 6.725±.040 | .275±.006 | 170.82±1.02 | 6.99±0.15 | 6-3/4 | 1/4 | 7-1/4 |

| -441 | 6.975±.040 | .275±.006 | 177.17±1.02 | 6.99±0.15 | 7 | 1/4 | 7-1/2 |

| -442 | 7.225±.045 | .275±.006 | 183.52±1.14 | 6.99±0.15 | 7-1/4 | 1/4 | 7-3/4 |

| -443 | 7.475±.045 | .275±.006 | 189.87±1.14 | 6.99±0.15 | 7-1/2 | 1/4 | 8 |

| -444 | 7.725±.045 | .275±.006 | 196.22±1.14 | 6.99±0.15 | 7-3/4 | 1/4 | 8-1/4 |

| -445 | 7.975±.045 | .275±.006 | 202.57±1.14 | 6.99±0.15 | 8 | 1/4 | 8-1/2 |

| -446 | 8.475±.055 | .275±.006 | 215.27±1.40 | 6.99±0.15 | 8-1/2 | 1/4 | 9 |

| -447 | 8.975±.055 | .275±.006 | 227.97±1.40 | 6.99±0.15 | 9 | 1/4 | 9-1/2 |

| -448 | 9.475±.055 | .275±.006 | 240.67±1.40 | 6.99±0.15 | 9-1/2 | 1/4 | 10 |

| -449 | 9.975±.055 | .275±.006 | 253.37±1.40 | 6.99±0.15 | 10 | 1/4 | 10-1/2 |

| -450 | 10.475±.060 | .275±.006 | 266.07±1.52 | 6.99±0.15 | 10-1/2 | 1/4 | 11 |

| -451 | 10.975±.060 | .275±.006 | 278.77±1.52 | 6.99±0.15 | 11 | 1/4 | 11-1/2 |

| -452 | 11.475±.060 | .275±.006 | 291.47±1.52 | 6.99±0.15 | 11-1/2 | 1/4 | 12 |

| -453 | 11.975±.060 | .275±.006 | 304.17±1.52 | 6.99±0.15 | 12 | 1/4 | 12-1/2 |

| -454 | 12.475±.060 | .275±.006 | 316.87±1.52 | 6.99±0.15 | 12-1/2 | 1/4 | 13 |

| -455 | 12.975±.060 | .275±.006 | 329.57±1.52 | 6.99±0.15 | 13 | 1/4 | 13-1/2 |

| -456 | 13.457±.070 | .275±.006 | 342.27±1.78 | 6.99±0.15 | 13-1/2 | 1/4 | 14 |

| -457 | 13.975±.070 | .275±.006 | 354.97±1.78 | 6.99±0.15 | 14 | 1/4 | 14-1/2 |

| -458 | 14.475±.070 | .275±.006 | 367.67±1.78 | 6.99±0.15 | 14-1/2 | 1/4 | 15 |

| -459 | 14.975±.070 | .275±.006 | 380.37±1.78 | 6.99±0.15 | 15 | 1/4 | 15-1/2 |

| -460 | 15.475±.070 | .275±.006 | 393.07±1.78 | 6.99±0.15 | 15-1/2 | 1/4 | 16 |

| -461 | 15.955±.075 | .275±.006 | 405.26±1.91 | 6.99±0.15 | 16 | 1/4 | 16-1/2 |

| -462 | 16.455±.075 | .275±.006 | 417.96±1.91 | 6.99±0.15 | 16-1/2 | 1/4 | 17 |

| -463 | 16.955±.080 | .275±.006 | 430.66±2.03 | 6.99±0.15 | 17 | 1/4 | 17-1/2 |

| -464 | 17.455±.085 | .275±.006 | 443.36±2.16 | 6.99±0.15 | 17-1/2 | 1/4 | 18 |

| -465 | 17.955±.085 | .275±.006 | 456.06±2.16 | 6.99±0.15 | 18 | 1/4 | 18-1/2 |

| -466 | 18.455±.085 | .275±.006 | 468.76±2.16 | 6.99±0.15 | 18-1/2 | 1/4 | 19 |

| -467 | 18.955±.090 | .275±.006 | 481.46±2.29 | 6.99±0.15 | 19 | 1/4 | 19-1/2 |

| -468 | 19.455±.090 | .275±.006 | 494.16±2.29 | 6.99±0.15 | 19-1/2 | 1/4 | 20 |

| -469 | 19.955±.095 | .275±.006 | 506.86±2.41 | 6.99±0.15 | 20 | 1/4 | 20-1/2 |

| -470 | 20.955±.095 | .275±.006 | 532.26±2.41 | 6.99±0.15 | 21 | 1/4 | 21-1/2 |

| -471 | 21.955±.100 | .275±.006 | 557.66±2.54 | 6.99±0.15 | 22 | 1/4 | 22-1/2 |

| -472 | 22.940±.105 | .275±.006 | 582.68±2.67 | 6.99±0.15 | 23 | 1/4 | 23-1/2 |

| -473 | 23.940±.110 | .275±.006 | 608.08±2.79 | 6.99±0.15 | 24 | 1/4 | 24-1/2 |

| -474 | 24.940±.115 | .275±.006 | 633.48±2.92 | 6.99±0.15 | 25 | 1/4 | 25-1/2 |

| -475 | 25.940±.120 | .275±.006 | 658.88±3.05 | 6.99±0.15 | 26 | 1/4 | 26-1/2 |

| Boss Seal Size: | Actual I.D. Inches | Actual C.S. Inches | Actual I.D. Millimeters | Actual C.S. Millimeters |

|---|---|---|---|---|

| -901 | .185±.005 | .056±.003 | 4.70±0.13 | 1.42±0.08 |

| -902 | .239±.005 | .064±.003 | 6.07±0.13 | 1.63±0.08 |

| -903 | .301±.005 | .064±.003 | 7.65±0.13 | 1.63±0.08 |

| -904 | .351±.005 | .072±.003 | 8.92±0.13 | 1.83±0.08 |

| -905 | .414±.005 | .072±.003 | 10.52±0.13 | 1.83±0.08 |

| -906 | .468±.005 | .078±.003 | 11.89±0.13 | 1.98±0.08 |

| -907 | .530±.007 | .082±.003 | 13.46±0.18 | 2.08±0.08 |

| -908 | .644±.009 | .087±.003 | 16.36±0.23 | 2.21±0.08 |

| -909 | .706±.009 | .097±.003 | 17.93±0.23 | 2.46±0.08 |

| -910 | .755±.009 | .097±.003 | 19.18±0.23 | 2.46±0.08 |

| -911 | .863±.009 | .116±.004 | 21.92±0.23 | 2.95±0.10 |

| -912 | .924±.009 | .116±.004 | 23.47±0.23 | 2.95±0.10 |

| -913 | .986±.010 | .116±.004 | 25.04±0.26 | 2.95±0.10 |

| -914 | 1.047±.010 | .116±.004 | 26.59±0.26 | 2.95±0.10 |

| -916 | 1.171±.010 | .116±.004 | 29.74±0.26 | 2.95±0.10 |

| -918 | 1.355±.012 | .116±.004 | 34.42±0.30 | 2.95±0.10 |

| -920 | 1.475±.014 | .116±.004 | 37.47±0.36 | 3.00±0.10 |

| -924 | 1.720±.014 | .116±.004 | 43.69±0.36 | 3.00±0.10 |

| -928 | 2.090±.018 | .116±.004 | 53.09±0.46 | 3.00±0.10 |

| -932 | 2.337±.018 | .116±.004 | 59.36±0.46 | 3.00±0.10 |

Understanding O-Ring Sizes

O-rings come in various sizes, and there are several standards that define these sizes. The most common standards include AS568, ISO3601, and JIS, among others. Each standard has its own set of specifications, which are crucial for applications that demand precision.

Custom O-Rings

For applications that require unique dimensions or materials, custom O-rings are the ideal solution. Custom O-rings can be manufactured to meet specific requirements, ensuring a perfect fit and performance in specialized applications.

Metric O-Rings

Metric O-rings are measured using the metric system and are commonly used in applications that follow international standards. They are essential for global industries where equipment and machinery often adhere to metric specifications.

JIS O-Rings

The Japanese Industrial Standards (JIS) O-rings are used predominantly in Japan and other countries that follow JIS standards. These O-rings are known for their precision and reliability in various industrial applications.

Popular O-Ring Standards

AS568 O-Rings

The AS568 standard, established by the Aerospace Size Standard, is widely used in the United States. It defines O-ring sizes in both imperial and metric units, making it a versatile choice for various applications. AS568 O-rings are commonly found in aerospace, automotive, and industrial sectors.

ISO3601 O-Rings

ISO3601 is an international standard that specifies the dimensions and tolerances for O-rings. It is widely recognized and used across the globe, ensuring compatibility and reliability in international markets. ISO3601 O-rings are crucial for industries that operate on a global scale.

Parker O-Rings

Parker Hannifin, a renowned manufacturer, provides a comprehensive range of O-rings that adhere to various international standards. Parker O-rings are known for their quality and performance, making them a preferred choice in critical applications.

Special Considerations

High Temperature O-Rings

In applications where extreme temperatures are a concern, high temperature O-rings are essential. These O-rings are made from materials that can withstand elevated temperatures without compromising their sealing capabilities. They are commonly used in industries such as oil and gas, automotive, and manufacturing.

USP Class VI O-Rings

USP Class VI O-rings meet stringent biocompatibility requirements, making them ideal for medical and pharmaceutical applications. They undergo rigorous testing to ensure they do not cause adverse biological reactions and can withstand sterilization processes like autoclaving and gamma radiation. These O-rings are essential for ensuring safety and compliance in sensitive applications.

Molded O-Rings

Molded O-rings are precision manufactured for specific applications and come in various materials and sizes. The molding process allows for complex geometries and tight tolerances, making these O-rings suitable for critical sealing applications in aerospace, automotive, and electronics industries. Their versatility ensures compatibility with different chemicals, temperatures, and pressures.

Spliced and Vulcanized O-Rings

Spliced and vulcanized O-rings are created by joining O-ring cord stock to form custom sizes, ideal for large or irregular applications. The process involves cutting the cord stock to length and joining the ends through adhesive or heat, followed by vulcanization to enhance durability and elasticity. These O-rings offer a cost-effective solution for specialized sealing needs without requiring expensive molds.

Quad Rings/X Rings

Quad rings, also known as X rings, feature a four-lobed design that offers enhanced sealing capabilities and better leak prevention compared to standard O-rings. The unique shape provides multiple sealing surfaces, reducing friction and wear while extending the O-ring’s lifespan. They are particularly effective in hydraulic and pneumatic systems requiring reliable, dynamic sealing.

Flat O-Rings

Flat O-rings have a flat cross-section, providing a larger contact area when compressed, which enhances their sealing capabilities. They are ideal for static sealing applications such as flanges, lids, and covers in various industries, including food processing, pharmaceuticals, and manufacturing. Their flat profile is beneficial in applications with space constraints or low-profile seal requirements.

Square O-Rings

Square O-rings have a square cross-section, offering an increased sealing surface area, making them ideal for high-pressure or high-vacuum environments. The larger contact area improves sealing performance and makes them suitable for dynamic applications where the seal needs to withstand movement and pressure changes. They are widely used in industrial, automotive, and aerospace applications.

Understanding the various O-ring standards and sizes is key to selecting the right component for your application. Whether you need custom O-rings, metric O-rings, JIS O-rings, Parker O-rings, AS568 O-rings, ISO3601 O-rings, or high temperature O-rings, Exactseal will help you find the perfect match. For specialized requirements, don’t hesitate to reach out for custom solutions tailored to your needs via Request for Quote form.