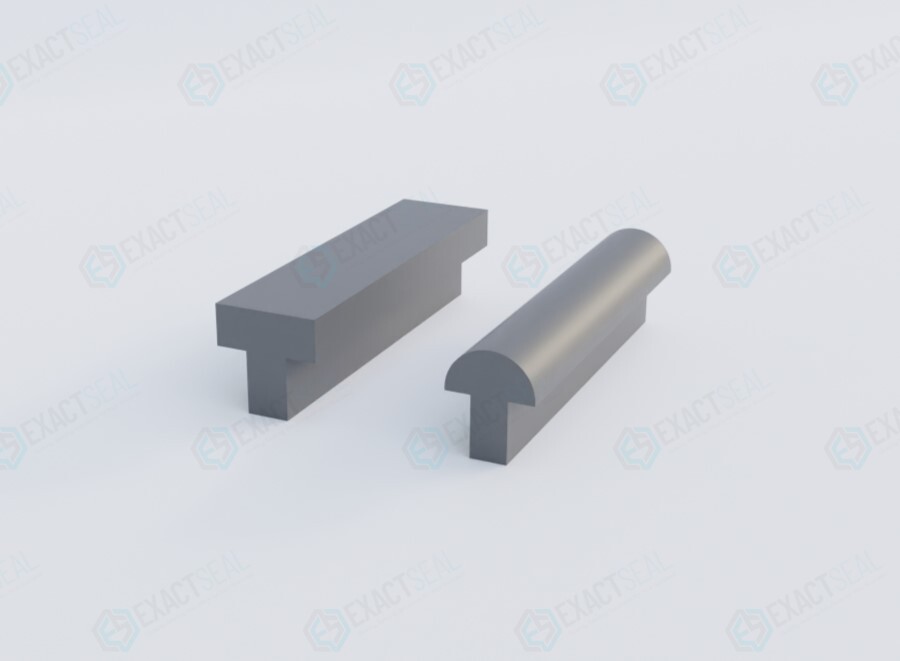

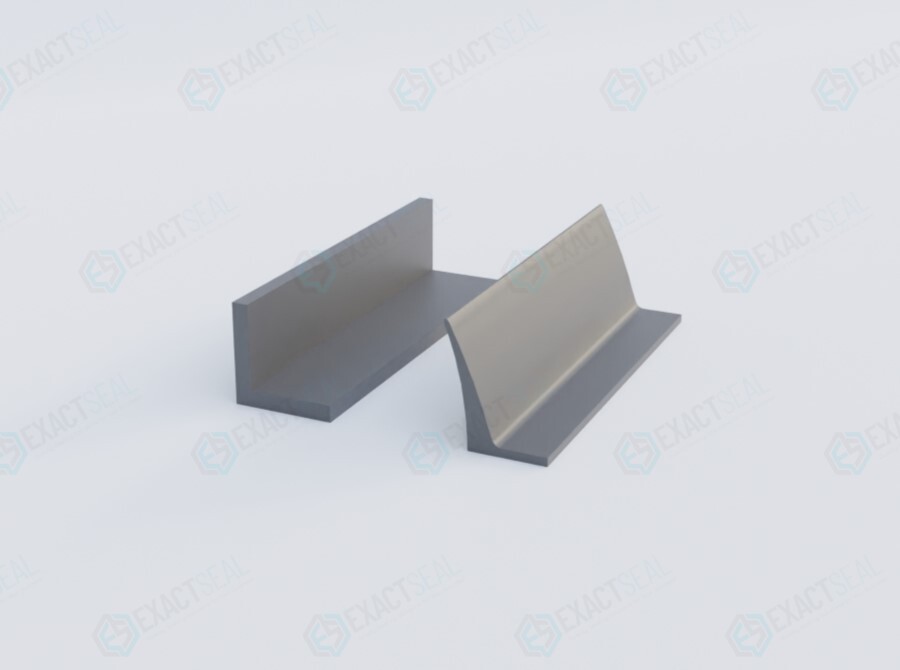

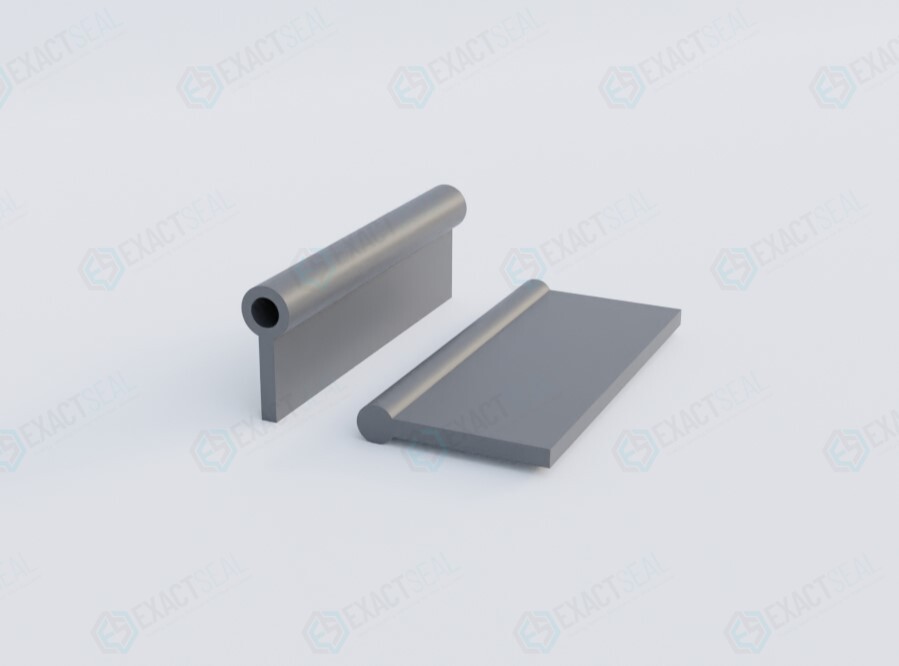

Extruded Rubber Strips

Key Features

| Premium material with excellent durability |

| Versatile functionality across a broad temperature range |

| FDA approval for safe food contact |

| Resistant to weathering, UV, and Ozone |

| Highly adaptable with superior sealing properties |

At Exactseal, we’re proud to offer a comprehensive range of premium quality extruded rubber strips designed to meet the diverse needs of our customers. With our state-of-the-art manufacturing facilities and expertise in rubber extrusion, we deliver superior products that excel in performance, durability, and versatility. Rubber Extruded Strips are also known as Rubber Strips and Rubber Seal Strips. Sometimes, these strips are also known based on their applications or materials, such as Silicone Strips and Rubber Weather Strips.

Get Exceptional Performance and Durability With Our Extruded Rubber Strips

We engineer our extruded rubber strips to withstand the harshest conditions while maintaining optimal performance and durability. Utilizing premium quality materials and advanced manufacturing techniques, our strips offer excellent resistance to abrasion, chemicals, weathering, and UV exposure. With their long-lasting reliability, you can trust our rubber strips to provide consistent protection and performance in any environment.

Customized Solution for every applications

Our extruded rubber strips are highly customizable to suit a wide range of applications and requirements. Whether you need specific dimensions, materials, or surface finishes, our expert team can tailor a solution to meet your unique needs. With our commitment to customization and innovation, we ensure that our rubber strips provide the perfect sealing and protection solution for your project. We meticulously engineer our rubber strips to offer superior sealing solutions. This effectively prevents air and moisture infiltration in doors, windows, and other openings. Whether it’s for residential or commercial purposes, our rubber weather strips are designed to withstand harsh environmental conditions, ensuring long-lasting durability and optimal performance.

We serve every industries!

Our extruded rubber strips find versatile applications across a wide range of industries, providing reliable sealing, insulation, and protection solutions. Whether it’s sealing doors and windows, cushioning and isolating vibrations, or protecting edges and surfaces, our rubber strips deliver superior performance and reliability. From automotive and construction to marine and HVAC, our strips contribute to improved efficiency, safety, and durability in various applications.

Your requirements, our Extruded Rubber Strips.

At Exactseal, we understand that every project is unique. Which is why we offer a wide range of customization options to meet your specific requirements. From material selection and profile design to color matching and special coatings, our team works closely with you. We aim to develop a tailored solution that meets your exact needs. With our technical expertise and responsive customer support, we ensure a seamless experience from concept to delivery. This provides you with the confidence and peace of mind you deserve.

Specifications

| Application | Catering environments, Food/drink container, Seals, Edge trim, Gap filler, Construction industries, Electronic applications, Marine applications |

| Product | Rubber strips |

| Material | Silicone, EPDM, Neoprene, Nitrile (Buna-N), FKM (Viton), FFKM (Kalrez), TPE, TPV |

| Colour | Black, White, Red oxide, Blue, Translucent |

Applications

| Automotive sector |

| Catering settings |

| Food/drink containers |

| Sealing applications |

| Edge trimming |

| Gap filling |

| Construction industries |

| Electronic applications |

| Marine applications |

Technical Information

| Property | Value |

|---|---|

| Hardness (Shore A) | 40°, 60° |

| Maximum Temperature | 200°C |

| Minimum Temperature | -40°C |

| Temperature Range | -40°C to 200°C, intermittent use up to 230°C |

| Durability and Flexibility | Superior sealing properties, shape memory for multiple uses |

| Compliance | FDA 177.2600 and EC 1935/2004 specifications |